The post Microfactory: Solution for the Future of Textile Industry appeared first on Caspar.

]]>Textile industry is changing.

Decades of being based on mass production have led to textile (fashion) industry being one of the leading environmental threats. Now, it is finally heading in a new direction – sustainability.

Sameness is replaced by individualism, corporate dictation is replaced by young designers, and mass print is being dethroned by custom print (on order).

Well, let’s start at the beginning.

Let’s see how things worked until recently.

Textile industry: the old way

Up until now, the textile industry was based on a few steps. First a design was created, a product was made, and then large amounts of this product were manufactured. In the end, this resulted in large stocks of products, the ones that can fulfil retail demands.

However, this is everything but sustainable. A huge portion of these products will end up as waste when a new collection hits the shelves, and the manufacturing process is problematic in itself. Lots of waste material is being made, and the colours and fabrics used are not sustainable. Why? Because in this case, corporations need to save money on the manufacturing process (cheaper processes are not eco-friendly) to compensate for the production of these large quantities.

So round and round we go and fill the Earth with trash and pollution.

However, millennials are a new and different generation, and they have clearly declared that they want a different direction.

This new path has been supported by the arrival of digital print.

What exactly is this about?

Textile industry: new way

Individuality. Automatization. Digitalisation.

These are the guidelines that are leading the contemporary world and have found their way into the textile industry.

How does it work?

Simply put – instead of buying designs that someone else created, we come up with our own.

These designs are then digitally sent to the manufacturer (through a website or an app), and there they are printed on a product or a material. This way we don’t have large amounts of waste, and the manufacturing process is done locally, making it more sustainable.

This manufacturing process suits individual needs, young designers, influencers, craftspeople, small businesses and, most of all, nature. This process ensures a bright future of our planet and ourselves.

However, this process requires a high level of automatization and adaptability, something those classic factories cannot provide. Here is where microfactories come into the spotlight.

Microfactory

The idea of microfactories was first created in Japan in 1990.

These are the factories that are set in smaller spaces but have the ability to conduct a large number of processes – manufacturing, processing, packing and selling. How come?

Microfactories use modern technology that allows for a high level of automatization and digitalisation.

In other words, instead of needing five hours, two machines and five people to complete a process, in a microfactory it will be done in one hour, using one machine.

Well, all of this sounds great in theory, but what is it like in practice?

Let’s see how we do it at our microfactory – Caspar!

- Through an online customizer we receive the design from our buyer. Let’s say he wants it printed on a classic T-shirt.

- This design is then printed on a material this shirt is made of, Organic Single Cotton Jersey. We use eco-friendly textile inks that don’t require water, as well as digital print technology that is more sustainable.

- After we have printed the design, we cut the needed form and sew the T-shirt, making the amount of waste minimal.

- Et viola – the product is done! We only need to pack it and send it to the buyer.

So, the entire manufacturing process is done at our microfactory.

This doesn’t just suit the individuals’ needs. It works great for business owners that are looking for partners who can fulfil the needed quota, and can also go through all the production levels.

Here we reach another important thing for our factory – dropshipping.

Dropshipping

Microfactories’ partners are often start-ups and small businesses for which it isn’t profitable to invest in all the machinery, workforce and other processes needed to start manufacturing – it is still on a scale that is too small.

They will use dropshipping – a business model in which a third party does certain processes for a company.

So, you can open an online store, but Caspar will be the one that processes, manufactures and sends the items to your buyers. That’s right – you needn’t worry about logistics, machinery, storage or other equipment. These are the advantages of microfactories!

Do you like the way we do things?

Let’s cooperate – contact us and we will be glad to help you!

The post Microfactory: Solution for the Future of Textile Industry appeared first on Caspar.

]]>The post Digital Print and Pigment Inks – Get to Know Caspar Manufacturing Process! appeared first on Caspar.

]]>On several occasions we’ve mentioned how our production is environmentally friendly and sustainable. We believe in a better tomorrow and know that we need to change the direction of the fashion industry.

In order to accomplish this, we’ve had to introduce new and advanced technologies in our manufacturing process.

We appreciate transparency in our business, so we’d like to explain the whole process to you, as well as the path the fabric goes through at our facility. More precisely, we’ll explain what digital print is, what are pigment inks and how and why we use them.

Don’t worry, we’ll use completely understandable vocabulary, without that bunch of technological terms.

Are you ready?

Here we go!

What type of print do we use?

First, we’ll explain what the printing process used to look like.

If you wanted to print a pattern, you needed to put it on printing plate first, or run it through a silk screen. Therefore, more material, more work. These technologies are still used, primary because they work well for larger amounts of products.

However, we opted for digital print.

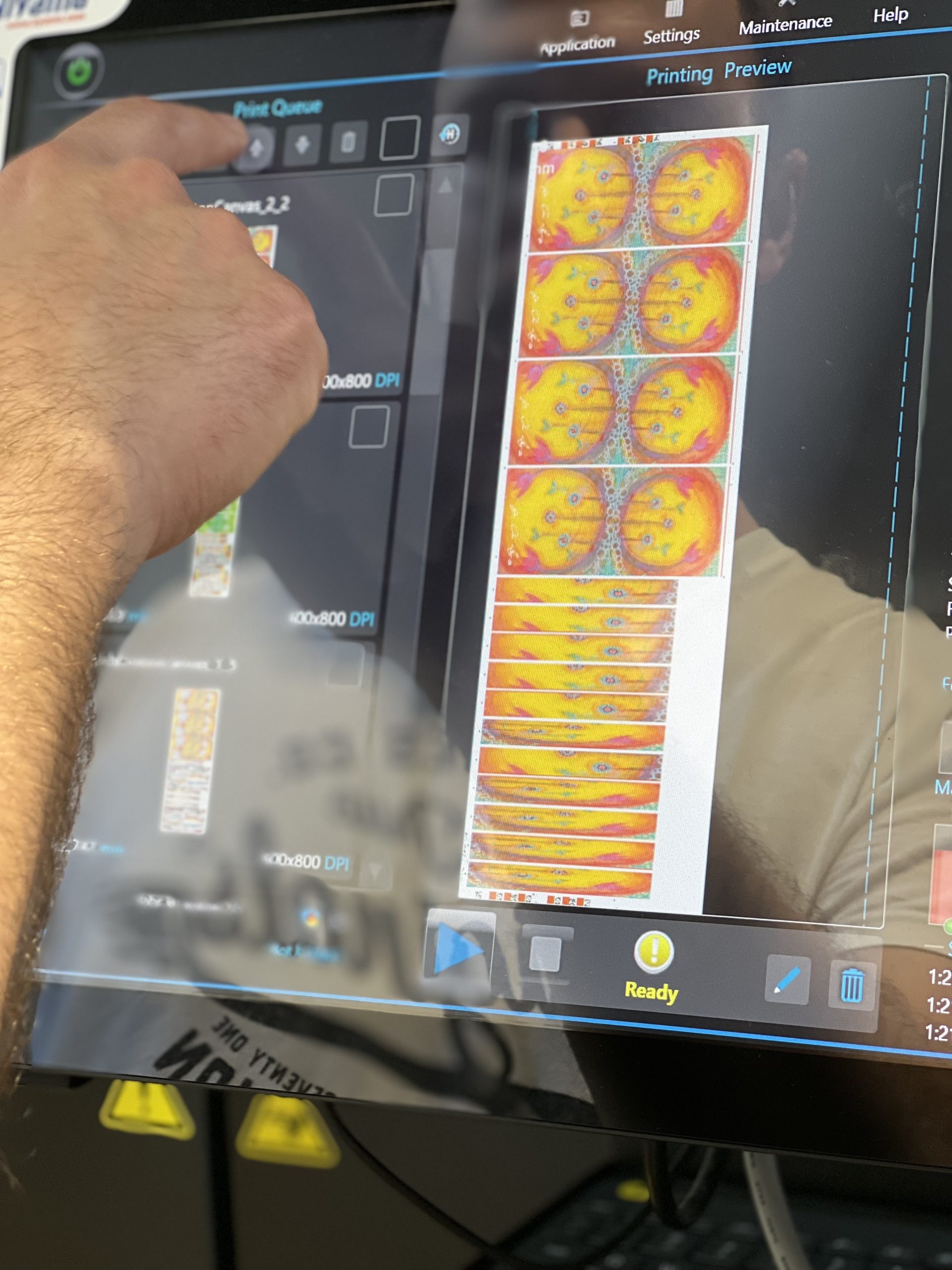

How does it work? We input data (in our case colours and patterns) into the computer, while the computer transmits these data into the printing machines which do the rest of the work.

Why is digital print better for our way of doing business?

- No more printing plates or screens, meaning faster printing process.

- It’s suitable for all types of materials. From natural ones like cotton, to artificial ones like polyester, digital print guarantees vivid colours and good adhesion.

- Great solution for small and medium editions. With digital print, there are no “minimum quantities”. At Caspar you can even get one meter of a fabric or one piece of an item.

- It’s suitable for custom print, so it doesn’t produce unnecessary waste.

In conclusion, it’s clear that what we represent – a company that is here to help small and medium businesses and craftsmen, all the while maintaining a sustainable approach – digital print is the best option.

After we’ve chosen the type of print we want, the inks came next.

Print in the colours of sustainability

There are three types of inks we can use in digital print:

- pigment inks

- acid inks

- reactive inks

We’ve chosen a printing machine called Kornit Presto, which enables us to perform all of the processes related to digital print directly onto the fabric: print, softening and drying, all in one go.

By selecting the printing machine, we’ve chosen the type of inks we want, too.

Every ink is suited for a different type of technology, and our Kornit Presto comes hand in hand with pigment inks.

Still relatively new and unfamiliar in the world of print, pigment inks are not that popular, but we believe they’re going to take over the market soon, and we’re here to proudly represent them.

We believe in their advantages and we know that they are the best choice for our goals, but also the best option for textile industry in general.

Here’s why:

- Print and ink fixation are a part of the same process in production, which is not the case with acid and reactive inks.

- They have better UV endurance.

- They adhere magnificently and give intense results.

- They give excellent results when printing illustration patterns and photography.

Acid and reactive inks on fabric are first treated with chemicals, then printed, steamed and washed. The process is exactly as it seems – time consuming and wastes large amounts of water and energy. Since ecology is one of our main principles, this doesn’t suit us at all.

Pigment inks don’t acquire water (like the rest of them do) but only temperature in order to be heated up and fixed onto the fabric. Therefore, there’s no (large) consumption of water – this is what gives us sustainability.

Pigment inks can be used in different ways, and the final result is consistent, which gives us quality.

Now when we’ve cleared all of this, let’s conclude with all the advantages these technologies have when compared to the traditional ways of print.

Why do we do things this way?

Our factory is a proud microfactory.

In order to meet all custom print requirements (which is the way our factory works), we need to have a high level of technology, automatization and digitalisation. Digital print represents exactly that – since it works the same as classic printers (tiny drops of ink are placed onto the fabric), results are fast but efficient.

By doing custom print, we’re also reducing the amount of waste, while the use of pigment inks doesn’t require water in the printing process.

As a company which puts great emphasis on sustainability and eco-friendliness, this is of great importance for us, and we believe that it’s important for our costumers and clients, too.

We believe in the new direction of textile print which leads us to a brighter future!

Do you want to talk more about our production? Contact us – we’ll gladly have a cup of coffee with you!

The post Digital Print and Pigment Inks – Get to Know Caspar Manufacturing Process! appeared first on Caspar.

]]>The post What Makes us different? Fashion and Business Future, Caspar Style appeared first on Caspar.

]]>We’re not just another textile company on the market, we are here to change it.

How do we plan to do it?

Fashion industry is known to be one of the main environmental pollutants. Fashion industry is where the workers are exploited on a daily basis, and large fashion corporations smother the young designers that want to make it. They simply can’t express themselves in this vortex of mass production, bad materials and copies of the same designs.

Caspar is here to turn it all upside down!

Of course, we can’t do it without you.

Are you ready? We grabbed your hand and together we are heading into the production process. Here you can see how we plan to change the world!

Tailored to fit you and your ideas

Perhaps you’ve already heard about it, but we will once again mention our customizer. All AOP products in our web shop, as well as our fabrics, can be customised. Your design, your text, your craziest ideas can be on it.

Don’t worry – the prices you see in our store are print-included. Yes, there is no need to pay it extra.

But we didn’t stop there. Here are some other innovations:

- The minimum order is just 1 metre or one piece.

- For large quantities (above 30 metres) you get a discount.

- Sizes range from XXS to XXL, so everyone can find the one that will fit them.

Once you have made your order, we will prepare it and deliver it as soon as possible.

Also, we are especially proud of our products and fabrics, so let’s talk about that for a while.

Sustainable and eco-friendly

Slow fashion doesn’t mean we are slow (except maybe when we get up in the morning). Slow fashion is the opposite of the current fashion world where every five minutes there is a new trend, and mass production results in a bunch of garbage and pollution.

This movement encompasses:

- high quality products that last longer

- sustainable materials that can be recycled

- items produced on order

- fairtrade

By using certified eco-friendly products, the ones that guarantee quality and reliability. By sewing and printing on order. By using eco-friendly textile dyes that don’t require water. Microfactory and fairtrade concepts fit here as well, and we will talk about them later.

We are especially proud of the fact that we are the first ones on the market who offer custom, GOTS certified products. This international label is given to eco-friendly, sustainable products which have passed rigorous tests and fulfilled strict requirements. This way we rest assured that their manufacturing process is eco-friendly, from the beginning to the end.

Oh yes, we said we will explain microfactory and fairtrade!

Fairtrade

Fairtrade is not just another fancy term. Fairtrade is a movement that cooperates with manufacturers, companies and governments to make the manufacturing process fair.

How do they do it?

Fairtrade sets social, economic and ecological standards that must be fulfilled to protect the labourer’s rights and to preserve the environment. Some of these include:

- fair minimum wage

- protecting the worker’s rights

- normal working conditions

- no harmful chemicals in the manufacturing process

- lowering carbon emissions

What do we do at Caspar? We get our materials from responsible sources. We ensure all our workers fair wages and excellent working conditions, which include free Sundays, stimulations and bonuses and, of course, an excellent work team!

Microfactory

That’s right, our factory is a microfactory. No, this doesn’t mean there is just one machine in one room. Microfactory is a term that is used for small or medium operations that are largely automated by high technology. Why is this important?

Microfactories use less energy and materials in their production, i.e., they have less environmental impact.

Don’t let the name fool you – despite being ‘micro’, these factories can produce large quantities of products, in our case textiles and textile products.

Caspar’s factory has modern machines which use less energy in the manufacturing process (sewing, printing, tailoring, shipping), therefore they have less environmental impact.

We care about the Caspar community

We want to gather a merry, creative community around us. Our Caspar family.

We want to help the young designers, influencers and those creative individuals that are full of ideas. We want to give them a chance to show what they’ve got and impress the world with their creations.

Do you want to become a member? Just register on our website! We are so grateful for every new member that we will give you a special gift upon registration – a free sample pack! We believe it will help you with fabric selection

We’re not done yet – we strive for excellence and advancement, and we are sure we will soon have some more news that will lead us closer to our goals.

Do you want to stay in touch? In our weekly newsletters we will inform you about our news and special discounts so you don’t miss a thing!

The post What Makes us different? Fashion and Business Future, Caspar Style appeared first on Caspar.

]]>